Imagine walking into a warehouse and seeing forklifts buzzing around you. You can hear them beeping as they reverse, watch as they lift pallets and feel the floor vibrating beneath your feet. Now, imagine overseeing that warehouse and thinking about the responsibility that comes with managing such a complex environment. With so many people and machines in one space, safety is of utmost importance. That’s why we’ve created a comprehensive forklift checklist form that can be completed in just seconds.

Understanding the Importance of Regular Inspections

As a warehouse manager or employee, you’re responsible for maintaining a safe environment for everyone who enters your facility. That means taking steps to prevent accidents before they happen. With regular forklift inspections, you can identify any potential hazards and prevent equipment failure before it occurs.

As a warehouse manager or employee, you’re responsible for maintaining a safe environment for everyone who enters your facility. That means taking steps to prevent accidents before they happen. With regular forklift inspections, you can identify any potential hazards and prevent equipment failure before it occurs.

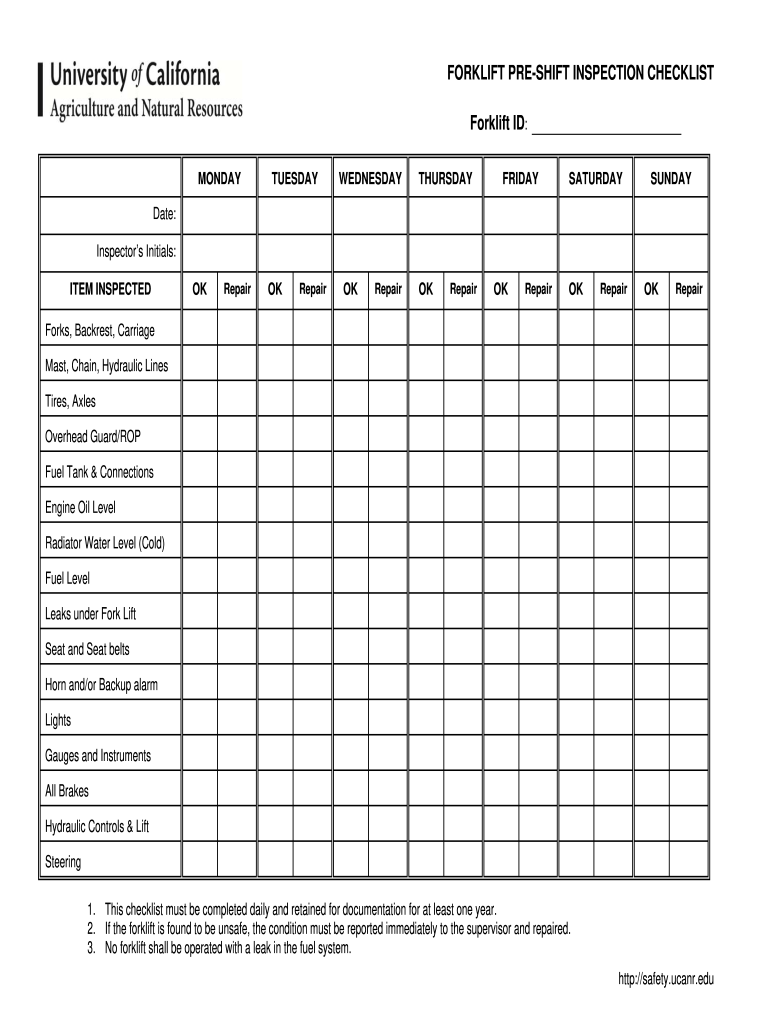

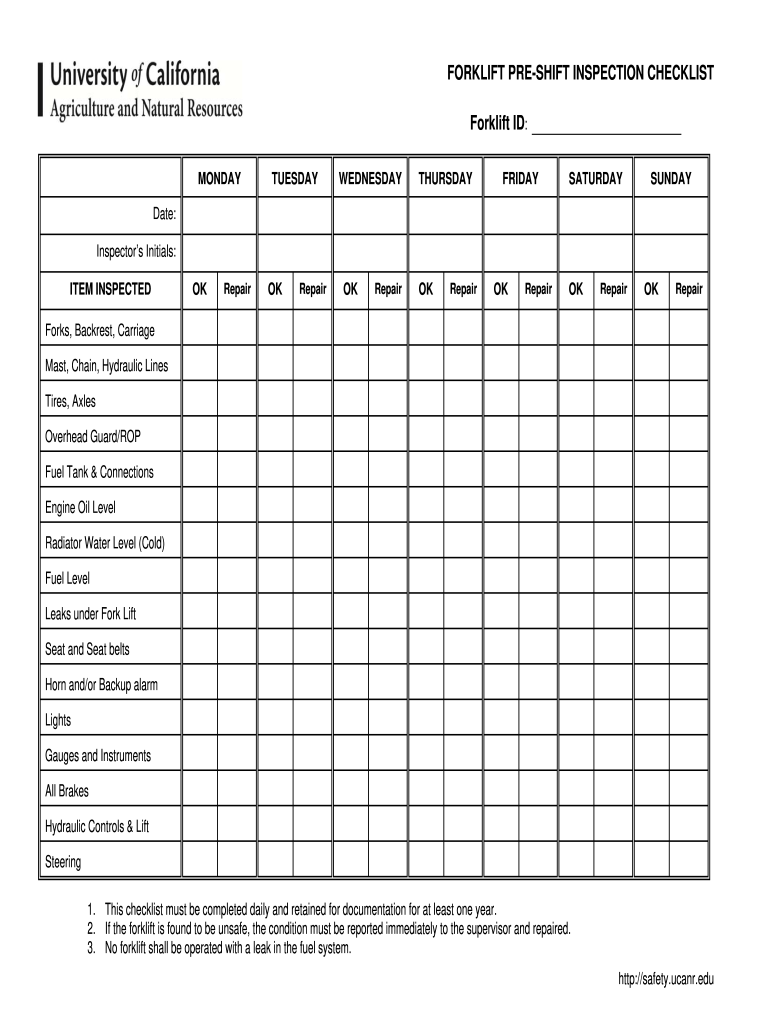

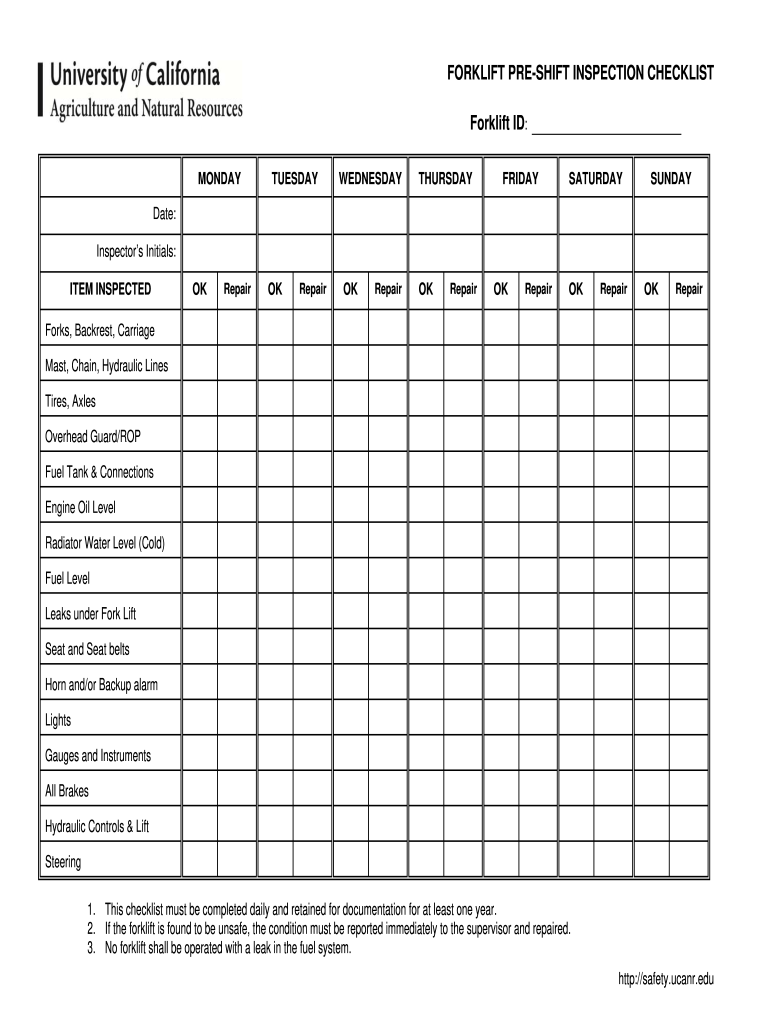

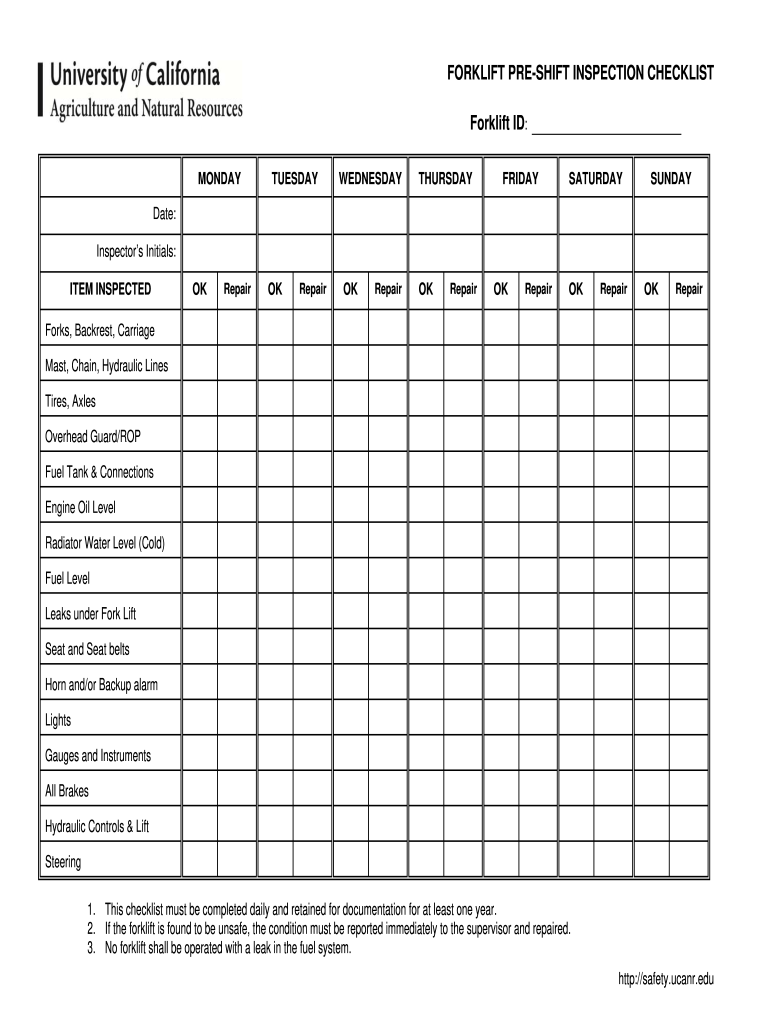

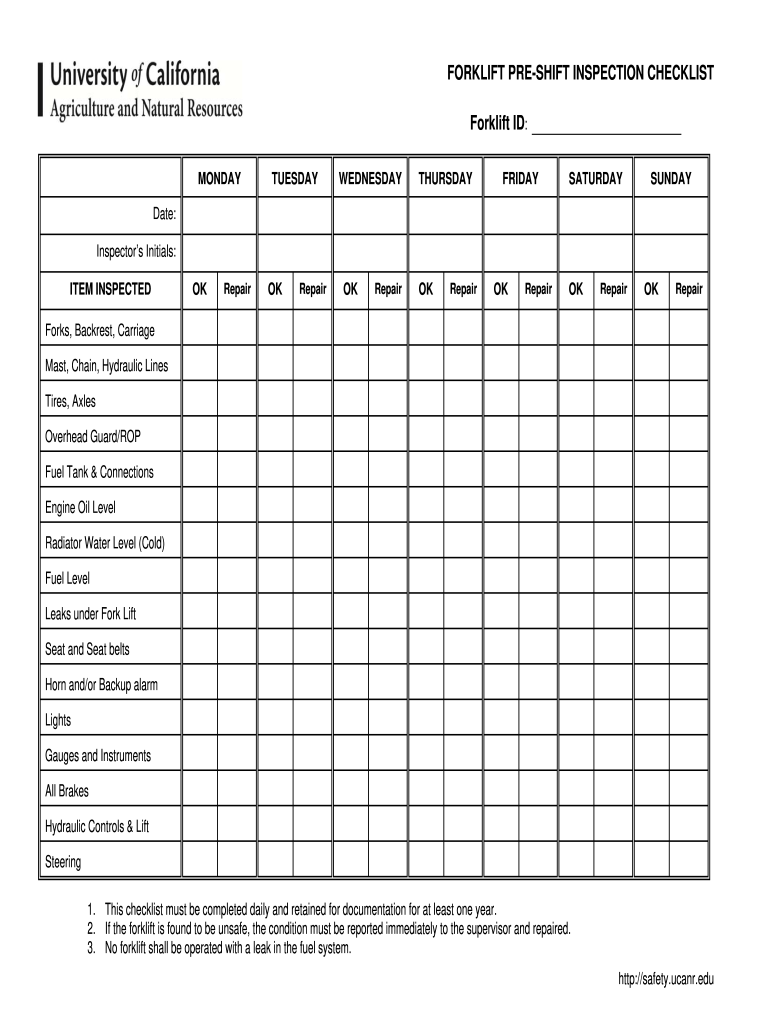

Every time a forklift is used, it should be inspected to ensure it’s in good working condition. That means checking the brakes, tires, steering, lights and other key components. With our forklift checklist form, you can complete this process in just seconds, giving you peace of mind knowing that your forklifts are in good condition and your workers are safe.

Filling Out the Forklift Checklist Form

Our forklift checklist form is designed to be simple and user-friendly. Even if you’ve never completed an inspection before, you’ll be able to understand and complete this form with ease.

Our forklift checklist form is designed to be simple and user-friendly. Even if you’ve never completed an inspection before, you’ll be able to understand and complete this form with ease.

Here’s how it works:

- Download and print our forklift checklist form

- Complete the form each time a forklift is used

- Check off each item on the list as you inspect it

- Make note of any issues on the form

- Sign and date the form to indicate that the inspection has been completed

It’s that easy! With just a few minutes of your time, you can ensure that your forklifts are in good working condition and your employees are safe.

The Benefits of Regular Forklift Inspections

Regular forklift inspections offer a number of benefits for both employers and employees. Here are just a few:

Regular forklift inspections offer a number of benefits for both employers and employees. Here are just a few:

- Prevent accidents: By identifying any potential issues before they become major problems, you can minimize the risk of accidents in your warehouse.

- Reduce downtime: When forklifts break down, it can cause significant downtime in your facility. Regular inspections can prevent this from happening by identifying minor issues and repairing them before they become major problems.

- Extend the life of your equipment: When you take care of your forklifts, they’ll last longer. That means you’ll get more use out of your equipment and save money in the long run.

- Keep your workers safe: Perhaps most importantly, regular forklift inspections help keep your workers safe. By identifying any potential hazards, you can take steps to prevent accidents before they happen and ensure that your employees are safe and healthy.

Creating a Culture of Safety in Your Warehouse

When it comes to workplace safety, everyone has a role to play. As a warehouse manager or employee, you can take steps to create a culture of safety in your facility. Here are a few tips:

When it comes to workplace safety, everyone has a role to play. As a warehouse manager or employee, you can take steps to create a culture of safety in your facility. Here are a few tips:

- Train your employees: Make sure that each employee who uses a forklift has received proper training. This includes both formal training and on-the-job training.

- Encourage reporting: Encourage your employees to report any potential hazards or issues they observe in the warehouse. This can help you identify areas for improvement and prevent accidents from happening.

- Lead by example: As a manager, it’s important that you lead by example. Follow all safety protocols and encourage your employees to do the same.

- Reward safe behavior: When you see employees following safety protocols, make sure to reward them. This can be as simple as giving them a shout-out in a team meeting or offering a small bonus.

By taking these steps, you can create a culture of safety in your warehouse that will benefit everyone who spends time there, from your employees to your customers.

Conclusion

If you’re a warehouse manager or employee, safety should be a top priority. With our forklift checklist form, you can take a simple step towards improving safety in your facility. By completing this form each time a forklift is used, you can identify any potential issues and prevent accidents before they happen. Plus, with regular inspections, you can extend the life of your equipment and reduce downtime in your facility.

If you’re a warehouse manager or employee, safety should be a top priority. With our forklift checklist form, you can take a simple step towards improving safety in your facility. By completing this form each time a forklift is used, you can identify any potential issues and prevent accidents before they happen. Plus, with regular inspections, you can extend the life of your equipment and reduce downtime in your facility.

Remember to take other steps, like training your employees, encouraging reporting and leading by example, to create a culture of safety in your warehouse. When everyone works together to prioritize safety, your facility will be a better place for everyone.