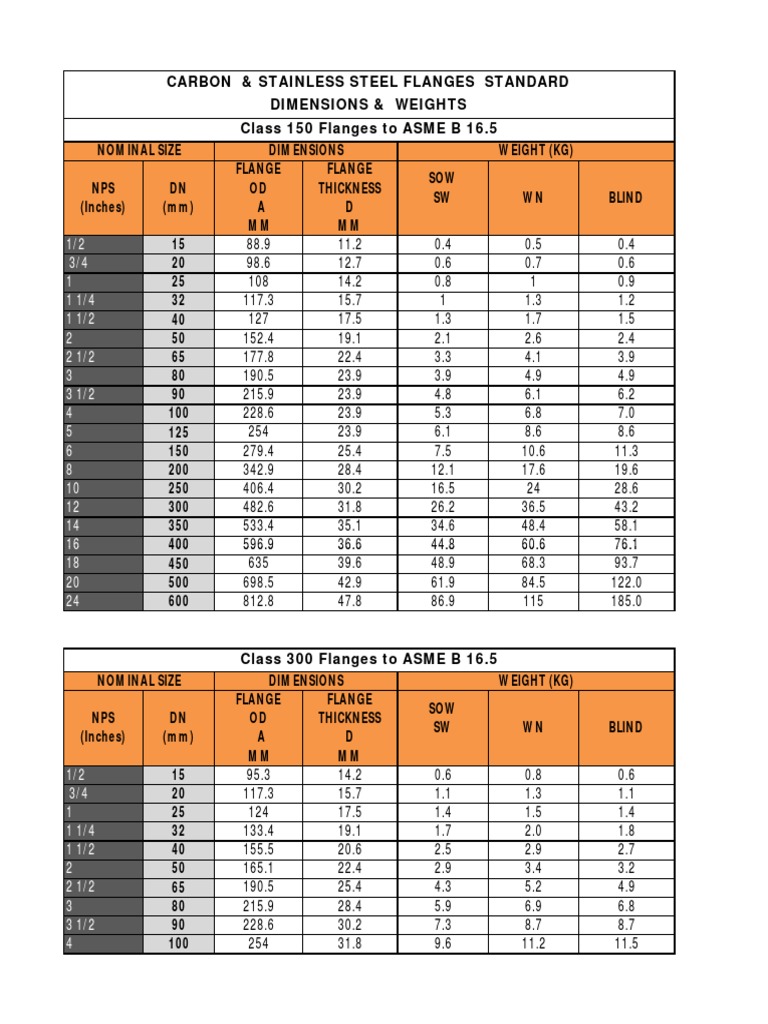

If you’re in need of a flange weight chart, we’ve got you covered. We’ve put together a comprehensive list of the most common flange weights, so you can easily determine the weight of your flanges and make sure you’re using the right equipment for your plumbing or mechanical engineering job.

Flange Weight Chart

Slip-On Flanges

Slip-on flanges are a popular type of flange that are easy to install and work well for low-pressure applications. They slip over the end of a pipe and are then welded in place. Slip-on flanges are generally less expensive than other types of flanges, but they also have a lower pressure rating and are not as strong as other options.

Slip-on flanges are a popular type of flange that are easy to install and work well for low-pressure applications. They slip over the end of a pipe and are then welded in place. Slip-on flanges are generally less expensive than other types of flanges, but they also have a lower pressure rating and are not as strong as other options.

Socket Weld Flanges

Socket weld flanges are another popular type of flange that are ideal for high-pressure applications. They are attached to the pipe using a socket weld connection, which provides a strong, leak-proof joint. Socket weld flanges have a higher pressure rating than slip-on flanges, but they are also more expensive and difficult to install.

Socket weld flanges are another popular type of flange that are ideal for high-pressure applications. They are attached to the pipe using a socket weld connection, which provides a strong, leak-proof joint. Socket weld flanges have a higher pressure rating than slip-on flanges, but they are also more expensive and difficult to install.

Blind Flanges

Blind flanges are used to seal piping systems or vessels, and they are typically used in situations where the end of a pipe needs to be blocked off. They are welded in place to provide a tight, leak-proof seal. Blind flanges are available in a variety of materials and sizes to meet the needs of different applications.

Blind flanges are used to seal piping systems or vessels, and they are typically used in situations where the end of a pipe needs to be blocked off. They are welded in place to provide a tight, leak-proof seal. Blind flanges are available in a variety of materials and sizes to meet the needs of different applications.

Lap Joint Flanges

Lap joint flanges are a unique type of flange that are typically used in piping systems that require frequent dismantling. They consist of two parts: a stub end and a lap joint flange. The stub end is welded to the pipe, while the lap joint flange slides over the stub end and is then bolted in place. This design allows for easy removal and replacement of the lap joint flange without having to cut the pipe.

Lap joint flanges are a unique type of flange that are typically used in piping systems that require frequent dismantling. They consist of two parts: a stub end and a lap joint flange. The stub end is welded to the pipe, while the lap joint flange slides over the stub end and is then bolted in place. This design allows for easy removal and replacement of the lap joint flange without having to cut the pipe.

So there you have it – a comprehensive guide to flange weights and types. No matter what type of plumbing or mechanical engineering job you’re working on, it’s important to choose the right flange for your application to ensure its safety and reliability. Use this information to make informed decisions about your flange choices and ensure a successful project.