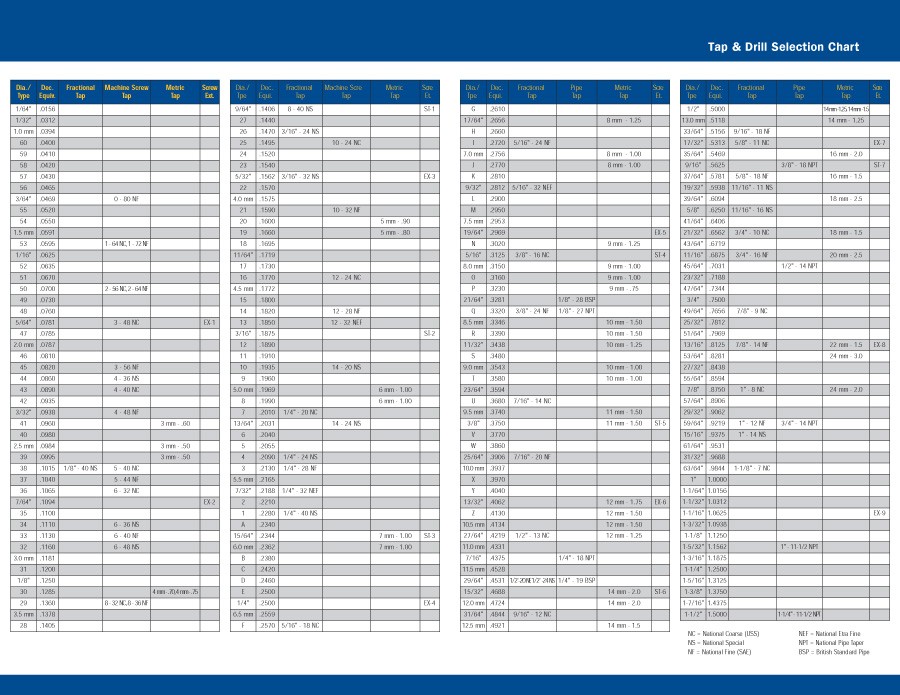

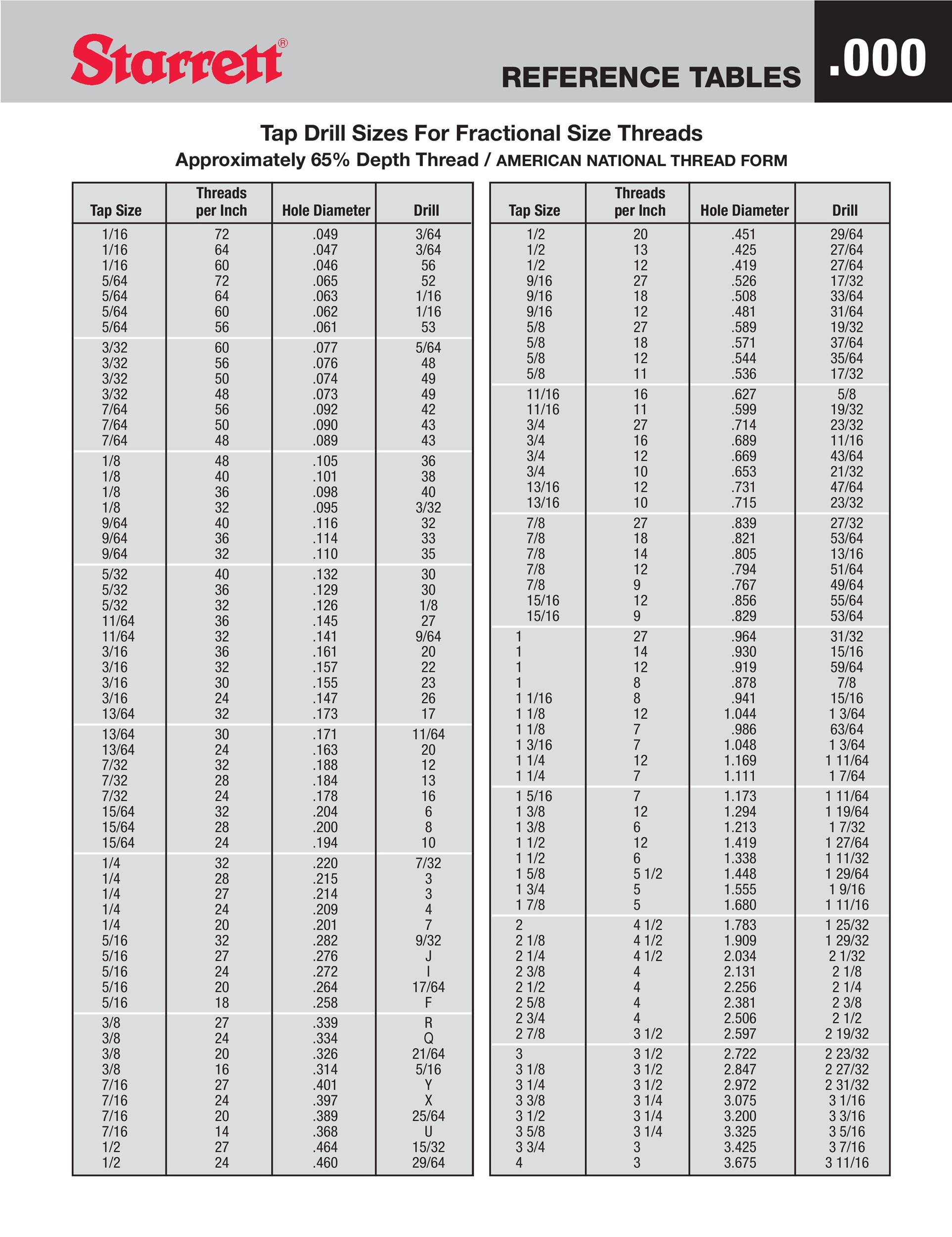

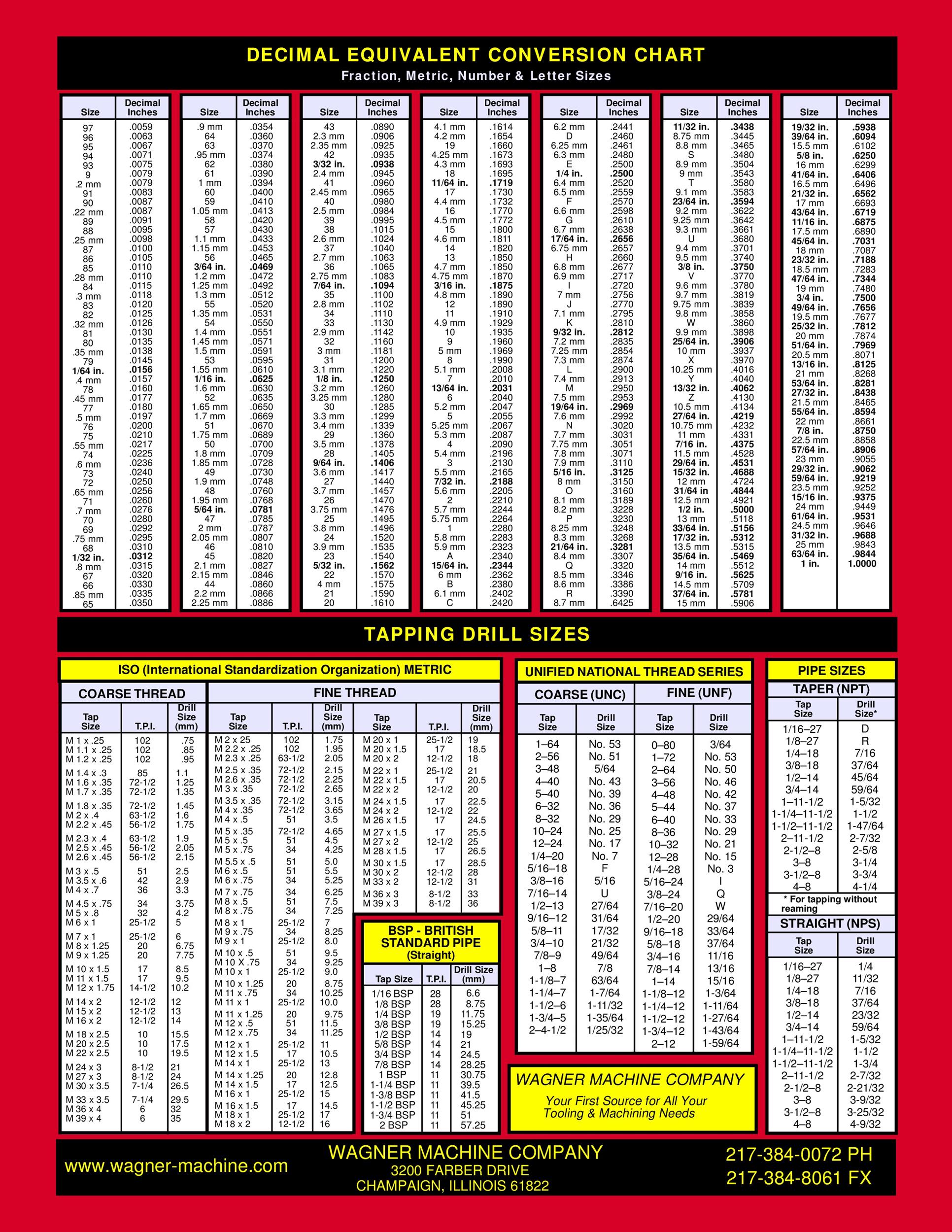

When it comes to the world of drilling, there are a lot of technical terms and specifications that must be taken into account. One such aspect is tap drill charts, which provide instructions for the size and placement of holes that must first be drilled before the final threads can be cut. To begin, it is important to understand the purpose of a tap drill chart. Essentially, these charts provide guidance on the necessary hole diameters for different types of threads. This is crucial for ensuring that the tap, which cuts the threads into the hole, fits properly and creates a secure connection. There are a few different types of tap drills that may be needed depending on the specific project. These include taper taps, plug taps, and bottoming taps. Each of these requires a slightly different hole diameter, and a tap drill chart can help determine what size is necessary for each one. One important thing to keep in mind is that tap drill charts are typically based on the use of standard taps. This means that if you are using a non-standard tap, you may need to make adjustments to the hole size accordingly. When looking at a tap drill chart, you will typically see a list of common thread sizes along with the corresponding drill diameter. The dimensions may be given in either inches or millimeters, depending on the chart. It is important to note that in some cases, the drill diameter listed on the chart may be slightly larger or smaller than the actual required size. This is because the hole size must be within a certain tolerance range in order to accommodate variations in tap sizes. Now that we have a basic understanding of tap drill charts, let’s take a look at some of the different types that are available. Taper Tap Drill Charts Taper taps are commonly used for creating starting threads in holes that will be threaded all the way through. These taps have a gradually decreasing diameter, allowing them to “guide” the threading process and ensure that the threads do not become damaged. To use a taper tap, you must first drill a hole that is slightly smaller than the tap’s diameter. This is where the taper tap drill chart comes in. The chart will tell you what size drill bit to use based on the thread size and type that you are working with. Here is an example of a taper tap drill chart for standard threads:

Taper Tap Drill Chart – Standard Threads

Size – TPI Drill Size

Size – TPI Drill Size

1/4" – 20 7/32"

5/16" – 18 21/64"

3/8" – 16 5/16"

7/16" – 14 23/64"

1/2" – 13 27/64"

9/16" – 12 31/64"

5/8" – 11 17/32"

3/4" – 10 21/32"

As you can see, this chart provides a list of common thread sizes along with the corresponding drill diameter in inches. For example, if you were working with a 1/2" – 13 thread, you would need to use a 27/64" drill bit for your taper tap. Plug Tap Drill Charts Plug taps are used for threading holes that do not go all the way through the material. These taps have a slightly larger diameter than taper taps, allowing them to cut the threads all the way to the bottom of the hole. When using a plug tap, you will need to drill a hole that is the same size or slightly smaller than the tap’s diameter. Again, a plug tap drill chart can help determine the appropriate hole size. Here is an example of a plug tap drill chart: Plug Tap Drill Chart – Standard Threads

Size – TPI Drill Size

Size – TPI Drill Size

1/4" – 20 13/64"

5/16" – 18 21/64"

3/8" – 16 5/16"

7/16" – 14 23/64"

1/2" – 13 27/64"

9/16" – 12 31/64"

5/8" – 11 17/32"

3/4" – 10 21/32"

As you can see, this chart is very similar to the taper tap chart, but the drill diameters are slightly larger. For example, if you were working with a 1/2" – 13 thread, you would need to use a 27/64" drill bit for your plug tap. Bottoming Tap Drill Charts Bottoming taps, also known as “plug taps with a longer thread,” are used for threading holes that have a very shallow depth (such as in a blind hole). These taps have a shorter chamfer and a longer thread length than standard plug taps, allowing them to reach the bottom of the hole more easily. Because bottoming taps require a very shallow hole, it is important to use the correct drill diameter in order to avoid drilling too deep. Here is an example of a bottoming tap drill chart: Bottoming Tap Drill Chart – Standard Threads

Size – TPI Drill Size

Size – TPI Drill Size

1/4" – 20 7/32"

5/16" – 18 21/64"

3/8" – 16 5/16"

7/16" – 14 23/64"

1/2" – 13 27/64"

9/16" – 12 31/64"

5/8" – 11 17/32"

3/4" – 10 21/32"

As you can see, this chart is very similar to the plug tap chart, but the drill diameters are slightly smaller. For example, if you were working with a 1/2" – 13 thread, you would need to use a 27/64" drill bit for your bottoming tap. Conclusion In conclusion, tap drill charts are an important tool for anyone working with threads and drilling. By providing guidance on the necessary hole diameters for different types of taps, these charts help ensure a secure and effective connection. Whether you are working with taper taps, plug taps, or bottoming taps, having a good understanding of these charts and their applications is crucial. With the information provided in this article, you should now be better equipped to use tap drill charts in your own projects.